Coal storage and handling is a common challenge faced in Thermal Power and Captive Thermal power plants. During the storage of coal, spontaneous combustion leads to the loss of useful coal. Spontaneous combustion occurs in coal piles when low-temperature oxidation slowly heats up the material to a volatile point. Moreover, the dusty conditions created by the coal, the dust particles are carried by the wind and cause pollution. This would pollute the plant area and could damage other utilities of the plant.

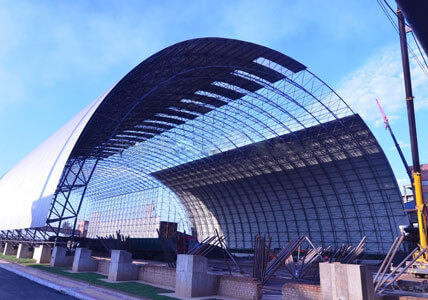

Coal shed is the best possible situation to overcome these problems during the storage of coal. Coal storage sheds are large in size and store tons of coals. Being the best choice for covering coal stockpiles for the most challenging environment, these types of sheds are also helpful in getting healthy predictions of spontaneous combustion & in taking appropriate precautions to avoid self-heating of coal during its storage and handling. By providing the covered storage, the operating expenses of the plant are also lowered.

When you are looking for efficient coal storage shed manufacturer then you should count upon us because we at Hindustan Alcox not only have advance technology but an excellent support of a well experienced, qualified and expert team. Over the last three decades, we have created a niche for ourselves in this industry. At our company, the team is committed to providing better designs, reliable manufacturing and good installation of the coal storage sheds that are in accordance with the principle of engineering. Hindustan Alcox is dedicated to providing the highest quality of work in every project.

We are manufacturing stacker reclaimer sheds with robust structures, reliable materials and precision-engineering to meet industrial requirements