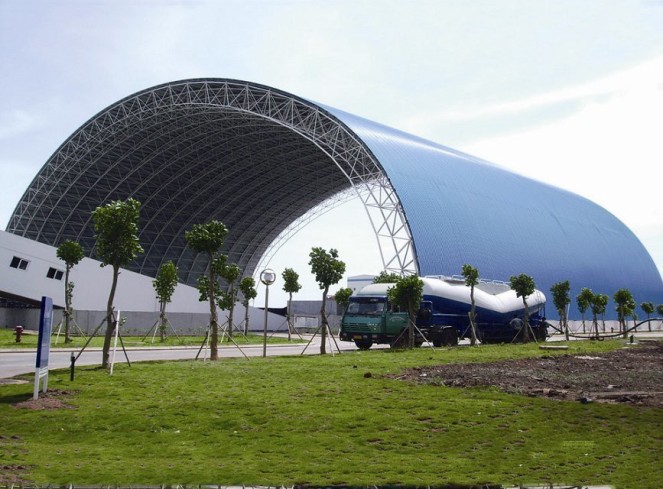

A geodesic dome is a thin shelled arrangements made out of triangles connected together to form a true sphere. The triangles are architecturally firm and distribute the stress throughout the dome, allowing the structure to bear heavy loads for their size. Space frame is the three dimensional framework that makes the dome structure stable.

These Geodesic Domes are the strongest, lightest and cost-effective building since it can cover space without any interior supports that usually cover up space in an interior. Not only it is cost effective but it is also easy to construct.

Things to keep in mind while Planning the construction of Geodesic Dome:-

- Designing the dome structure is the first step to start with. The size and the amount of triangles and their calculations to form the dome structure are needed.

- Struts: these are the framework for the dome which are made up of rods. Usually geodesic domes comprise of struts of different sizes.

- There are various cladding options which can be used based on the intended use of the building.

- Finalizing the structure: several things should be kept in mind while putting all the pieces together such as the struts and their dimensions, their edges flattered so that they fall on the same plane when attached, and to make sure the flattened edges bend slightly (found by calculation).

These types of dome structures are famous for their vast usage in, because the materials required are all environment friendly and the structure itself is very safe and creates spacious interior.

About Hindustan Alcox

We at Hindustan Alcox limited, one of the modern dome structure manufacturers use the combination of its basic features and latest technology to make dome structure more appealing and highly versatile in installation as well as in maintenance.